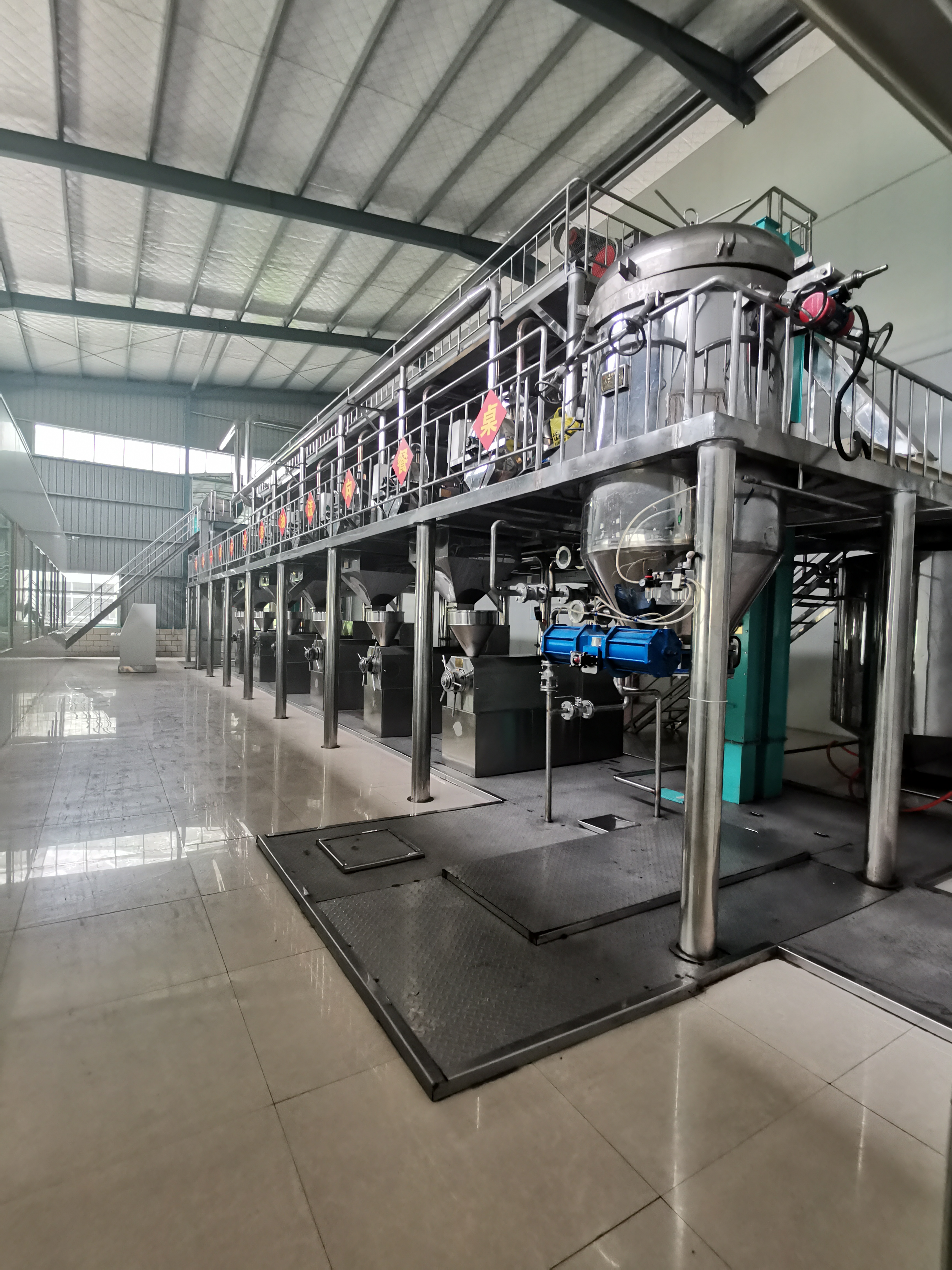

I. Low-temperature pressing system : The screw press operates in a low-temperature environment below 60℃ to avoid high temperature damage to the peanut protein structure. The oil yield is stable between 50% and 52% , and the acid value of the oil is ≤ 1.5mg/g .

Second and third refining processes :

Pre-filtration : 100-mesh stainless steel filter screen removes oil residue.

Winterization crystallization : waxy precipitation through stepwise cooling.

Activated clay adsorption : Decolorizes while raising the smoke point to above 230℃

III. Flavor-locking technology : Preserves the natural antioxidants in the peanut skin, and the preservation packaging extends the shelf life to 18 months .

.png)

.png)